Innovations

our expertise at your service

R+ lab is our R&D department, made up of several people with at least 20 years of experience in the biomass combustion industry.

The Nobis combustion system

The system keeps the flame balanced, maintaining optimal combustion over time, without the need for any adjustment.

Learn More

The Nobis combustion system

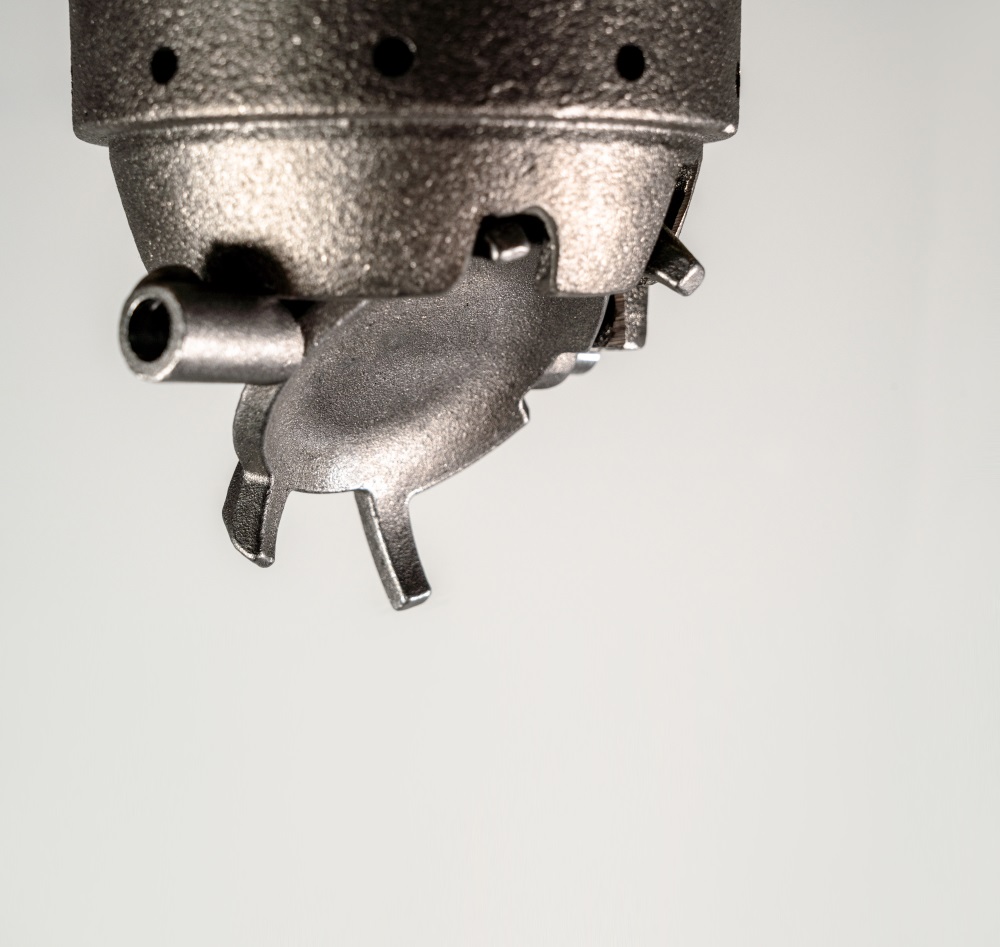

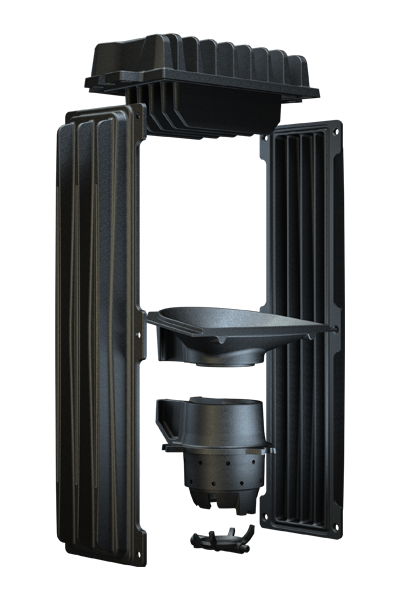

Nobis Combustion System

The new fire, always perfect.

The new brazier and new stove body allow a new and unique form combustion. The brazier is always clean, thanks to the automatic cleaning system, the flame is perfect thanks to the management of combustion air flows, and the view of the flame is clear and unobstructed thanks to the glass cleaning system, all ensuring minimal maintenance.

The NCS system allows the use of the majority of pellet types on the market by guaranteeing automatic combustion calibration.

The NCS system regulates combustion through monitoring of the varying conditions of the flue.

The NCS system allows the customer to clean the stove once every two weeks, simply by emptying the ash drawer.

The NCS system ensures automatic cleaning of the brazier not at a set interval, as with most other pellet products, but only when needed.

Nobis' "brushless" technology

The brushless loading system, in addition to reducing power consumption, guarantees silence, safety and loading precision with all types and sizes of pellets.

Learn More

Nobis' "brushless" technology

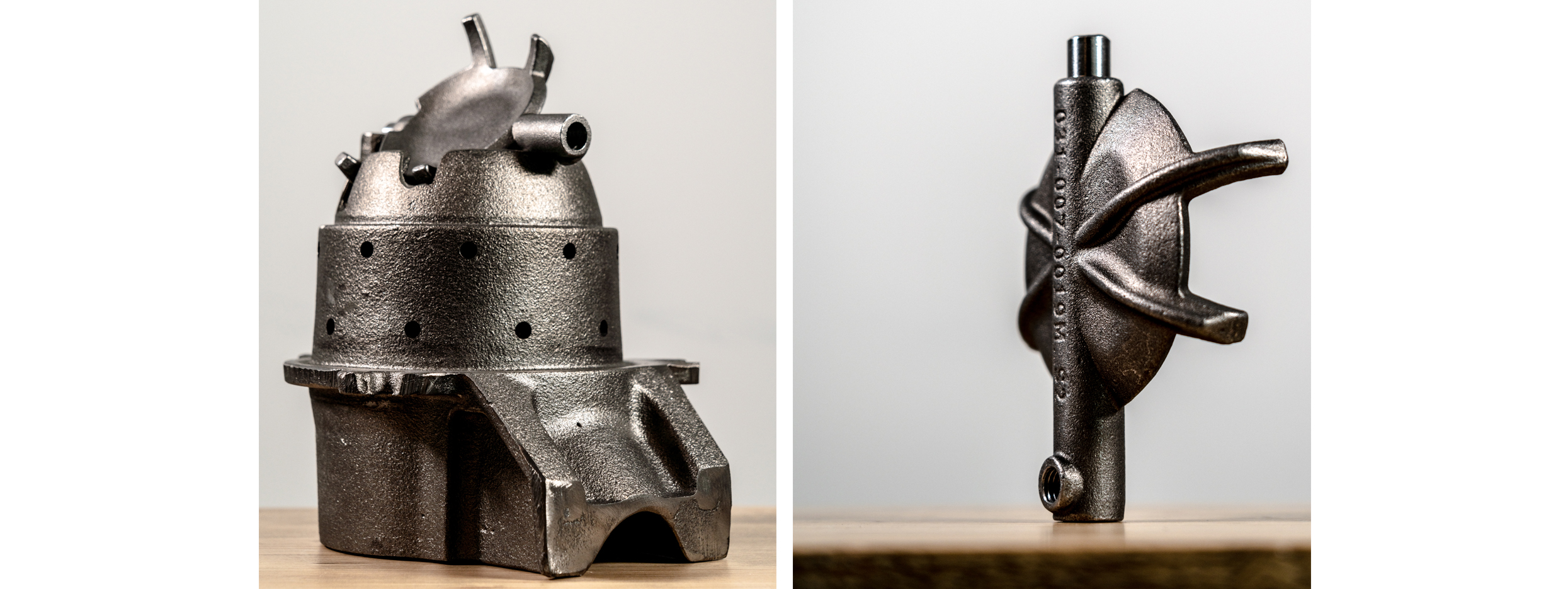

Nobis Brushless Technology

The new fire, always silent.

The pellet is loaded by a brushless gear motor. Unlike a brush motor, it does not require sliding electrical contacts (i.e. brushes) on the rotor shaft in order to operate. The switching of the current circulating in stator windings, and therefore the variation of the magnetic field orientation generated by them, takes place electronically. This ensures lower mechanical wear, considerably reducing the need for periodic maintenance and considerably reducing noise, precisely because no physical rubbing occurs. The brushless motor is electronically controlled by stove’s electronic board, which constantly monitors power absorption and torque, adjusting operation to the different types of pellets that may be used.

It therefore continuously adapts to load variations caused by different pellet types, and manages, in case of any need, the release mechanism. The structure of the brazier allows a lower suction motor speed to be used, thus guaranteeing optimal acoustic comfort. The circular shape of the brazier allows the flame to develop naturally, guaranteeing visual quality and excellent performance. The selected fans and the sizing of air passages guarantee maximum silence even when the stove is operating in ventilation mode. The cast iron exchangers have a very special shape. Each heat exchange fin exploits the Venturi effect to generate an increase in air speed without the need to use a forced ventilation system, exploiting the convective motion of the air to guarantee optimal speed without annoying noise effects.

Products born to last

The stove body is made of certified high thickness materials. The welding is completely robotized, in order to guarantee a constant quality over time.

Learn More

Products born to last

Nobis Timeless Construction

The new fire, built to last.

The stove body is made of high thickness certified materials. Welding is completely robotised, so as to guarantee a constant quality over time. The hermetic seal of every stove body is checked at the end of the production line. The thick cast iron exchangers guarantee strength and durability over time. All making a stove body born to last over time.

Safety Standards

A mechanical pressure sensor monitors the draught of the chimney and determines its correct operation.

Learn MoreSafety Standards

Nobis Safety Standard

The new fire, always safe.

‘Safety’ is a word all too easily used, though a principle we never take for granted. Our obsession with an ever increasingly safer product has led us to have standards never seen before in any product on the market. Our product is safer thanks to our software, which, integrated with practical solutions, manages and analyzes the operation of our stove. The use of a combustion chamber temperature sensor connected to a flue gas temperature sensor guarantees that everything is completely under control. Measurement of the pressure in the combustion chamber means that no troublesome clogging occurs. A mechanical pressure sensor monitors the draft of the flue and determines its correct operation. The brushless geared motor is managed by smart electronics, and works with any pellet to guarantee a constant pellet load in the brazier. Two newly developed anti-blast hatches are installed in the lower part of the gas flue. Micro-switches indicate the opening of the pellet loading door and of the ash drawer. A mechanical safety thermostat intervenes in case of overheating.

Nothing is left to chance, with all of the above components making the Nobis product among the safest on the market.

Shielded loading

The new loading system makes the pellet descent invisible, leaving a complete and pleasant view of the flame.

Learn MoreShielded loading

The fire free to shine

The new fire, beautiful to see.

The new combustion system hides the classic pellet descent tube, making the view of the combustion chamber more pleasing to the eye, while guaranteeing unparalleled flame quality.

Long-lasting glass cleaning

Thanks to a special engineering construction that exploits the movement of air, the front glass remains clean for a long time, ensuring a perfect enjoyment of the beauty of the fire.

Learn More

Long-lasting glass cleaning

Cleaner glass for longer

The new fire, the perfectly visible flame.

Two independent air ducts keep ash away from the glass, keeping it clean for longer.

Automatic cleaning system

The new cast iron brazier carries out cleaning cycles of the bottom in a fully automatic way and in the real moment of need.

Learn MoreAutomatic cleaning system

Automatic cleaning

The new fire, always clean.

Nobis’ innovative automatic cleaning system guarantees continuous operation without manual intervention for longer. The system works not at set intervals, like most systems on the market, but only when needed. In just 15 minutes, the stove switches off, cleans itself and re-ignites completely automatically, avoiding the cooling down of the heat exchangers.

elemento It monitors the operation and chooses the right time to perform the cleaning cycle.

Optimized consumption

The NCS system allows the use of most types of pellets on the market; thanks to the automatic combustion calibration, the system guarantees the best performance in terms of consumption for each type of pellet.

Learn MoreOptimized consumption

The new fire, better consumption.

elemento controls the temperature of the heat exchanger. Continuous temperature control ensures that the heat exchanger has constant 100% efficiency without unnecessary waste of heat or fuel.